ANNA's Engineering

Engineered for Beauty—and for Life

From the very beginning, we knew that creating a structure this dynamic and close to nature demanded engineering at the highest level. Every detail—from the smooth glide of the sliding shells to the precision of the foundation—was carefully considered to ensure not just elegance, but endurance.

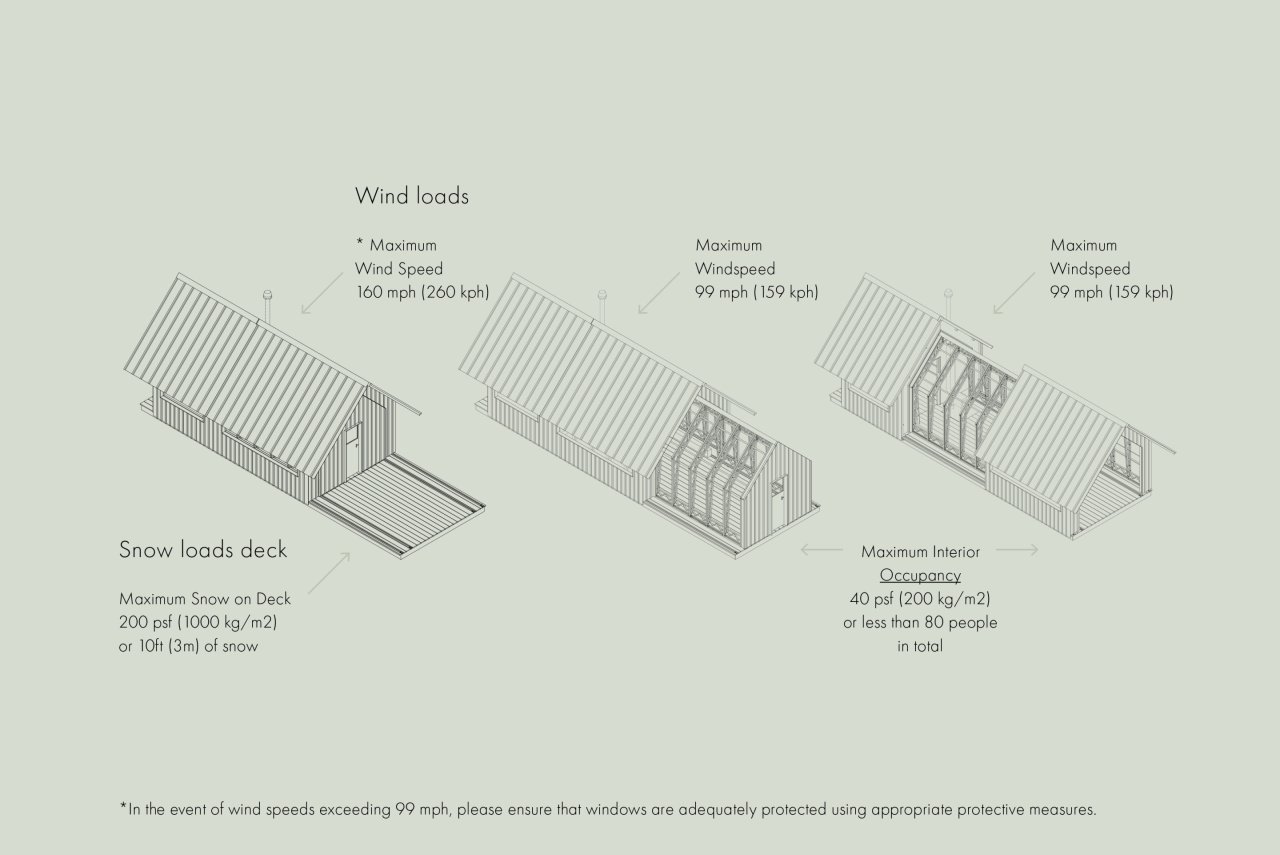

We partnered up with the best engineers, including those at ARUP, to rigorously model and optimize ANNA’s structural performance, and performed Finite Element Method (FEM) analysis to ensure ANNA's resilience under various loads and forces, such as wind and snow.

Together, we’ve built a cabin that is as strong as it is graceful—ready to weather storms, adapt to climates, and be assembled with ease, anywhere in the world.

These six core elements reveal the engineering behind the experience.

Structural Engineering

At the heart of ANNA’s design lies a patented rail system that ensures smooth movement while offering robust protection against the elements. A unique combination of a wind labyrinth, integrated brushes, and rubber seals forms a weather-tight seal between the structure’s moving layers, keeping nature at bay when needed, and inviting it in when desired.

To further enhance its resilience, ANNA is equipped with insulated double glazing and specially engineered trusses capable of withstanding wind speeds of up to 160 mph. These trusses are built from a core of 30mm A-quality plywood, reinforced with aluminum inserts, and finished in solid wood.

The angled 45-degree roof isn’t just a nod to traditional form; it’s a functional choice that enables snow to slide off easily, while the structure itself bears the weight of heavy snowfall with ease. Beneath it all, the platform is reinforced with high-density cross beams, giving ANNA its remarkable stability in even the harshest conditions.

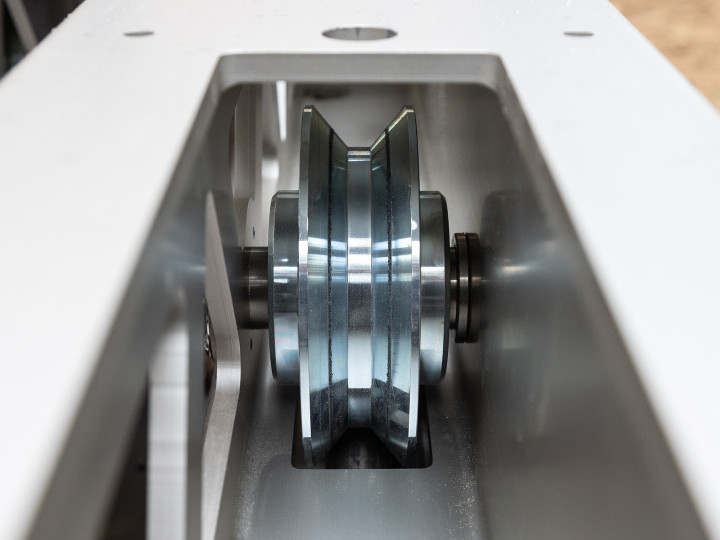

Move ANNA's Shells with Ease

Each of ANNA’s shells weighs over 3,000 kilos, yet can be moved by hand as easily as rolling your carry-on bag when traveling. This surprising smoothness is made possible by a system of precisely balanced steel rails and the highest-quality, low-friction German bearings. There are no motors or electronics involved, just the efficiency of good design. It’s a quiet, physical experience that connects you to the structure—and to the outdoors—every time you move it.

Contributing to the endurance of ANNA is the fact that, due to her modular nature, elements can be replaced over time. Much like in a car, ANNA's wheels can be replaced over time without compromising the shells.

ANNA's Brakes

ANNA is equipped with a patented brake system inspired by the simple efficiency of a bicycle hand brake. It allows users to effortlessly slow and gently stop the movement of the heavy shells, ensuring ease and control. This elegant mechanism enhances both safety and the tactile experience of opening and closing ANNA.

The Platform

A perfectly level platform is essential for smooth sliding. Traditional foundation systems often have tolerances that are too imprecise for our needs. That’s why we developed a custom frame that allows for micro-leveling and is compatible with various foundation types, including helical piles and concrete piers.

Optional Recessed Bed & Bathtub

A queen-size bed can be cleverly stored beneath the floor, raised and lowered with ease using a finely engineered spindle-and-winch system. It rises into view when needed and disappears when not, transforming the space with a simple turn. A sunken bath allows you to step down into comfort at eye level with the natural environment the cabin was designed to frame. This seamless integration of mechanical ingenuity and minimalist design supports flexible use of space while preserving the cabin’s calm, uncluttered interior.

Onsite Assembly

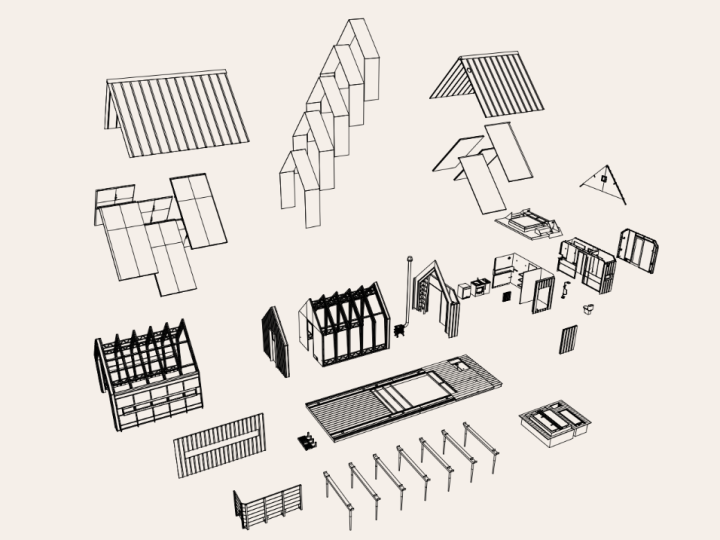

ANNA is delivered in modular components and shipped directly to the site. Installation takes just 3–4 weeks and requires no specialized tools, making assembly straightforward, yet precise.

Unlike many mobile structures, ANNA isn’t limited by road transport dimensions. Freed from those constraints, its design remains spacious and intentional. While engineered for permanence, ANNA can be disassembled if needed, offering both longevity and flexibility.

Every ANNA is placed with care. Its connection to the landscape is deliberate and site-specific, ensuring that each structure feels rooted in its surroundings.